Build a Solar Battery Charger For Ni-MH Batteries

Build a simple solar powered battery charger for Ni-MH batteries.

You could buy a solar powered battery charger, but it's cheaper and more fun to make one yourself.

If you're like me and you like to spend a lot of time in the backcountry, this means you don't have any way to charge you devices. You could go look at a commercial solar battery charger, but for popular brands, these can easily cost $100 or more. So why not build one yourself?

In its simplest form a battery charger applies a voltage, or current, to the positive terminal of a battery. This will cause the battery to charge and its voltage will increase. The only time I know of anybody charging a battery with such a simple system is jump starting a car. Just applying a voltage to a battery may charge it, but it has no system to protect the battery. Every battery's chemistry has unique properties, including but not limited to; nominal voltage, max voltage, energy density, self-discharge rate, internal resistance, and life cycle. Because of the unique requirements of each battery chemistry, it is important to first specify which battery chemistry we want to use.

Charging a Single AAA Battery

Battery Selection

Currently, there are 3 common rechargeable battery chemistries used for consumer devices. We have lithium ion, nickel metal hydride(Ni-MH), and nickel cadmium(NiCd). So let's start with the nominal voltage for lithium ion. It varies from 3.2 V to 3.7 V, Ni-MH is 1.2 V, and NiCd is also 1.2 V. Because most consumer devices use either internal batteries, AA, or AAA batteries. Let's eliminate the lithium ion because its nominal voltage is over twice the voltage of AA or AAA batteries. If we then compare the energy density of Ni-MH and NiCd, we find that Ni-MH has an energy density of 140-1,000 Wh/L and NiCd has an energy density of 50 - 150 Wh/L. So I'm going to use Ni-MH for the better energy density.

Battery Charging Methods

There are details in charging methods for all battery chemistries, and I recommend finding a good source of information for whichever chemistry you choose to work with. For Ni-MH, Panasonic and Energizer have both made excellent materials available.

In order to charge a battery fast (in under a few hours) a microcontroller is normally used to monitor both the battery voltage and temperature. If voltage begins to drop, then the battery has reached a state of overcharge and the charger shuts down. If temperature begins to rise rapidly, it could mean damage to the battery, or that a state of overcharge has been reached and the charger shuts down.

If time isn't a concern, another method is to slowly charge the battery with a timer to shut it down after 12 to 14 hours. To avoid overcharge, the battery charger requires that batteries have a minimum capacity. But if the batteries have a greater capacity than the minimum that the charger was designed for, they will not be fully charged. A simple solution but almost requires battery capacity to be specified by the charger.

Another option is to trickle charge the batteries. To fully charge an empty battery following Energizer's recommendations would take 60 hours. Not very practical for fully charging a battery, rather it is often used as a secondary charge method. Once the batteries are full, a trickle charge is started to keep the batteries "topped off".

Let's consider what might be the best method for our solar charger. The trickle charge will take too long, so let's discount it. The time-based charger also quickly runs into problems; if the solar charger lost power, the timer would reset, resulting in overcharging. This could be solved by adding a battery for just the timer. However, if power was lost, then the timer would still be going, but not charging the batteries, resulting in a battery that was not charged. Because of the long charge time of the timer method, it will almost always lose power. So the timer method is out. Using a microcontroller seems like a good choice, but it's a much more complex system. It will have to have a thermistor for each battery slot, and one to measure the ambient temperature. We also then have to measure voltage on every battery, and it may not be able to do the fast charging because of power limitations from the solar panel.

Every one of the presented methods seems to have limitations that cause concern. Instead of just using one of these methods, I propose a method that takes components of the timer and microcontroller methods. We use a comparator to monitor voltage and prevent overcharge, but use the low charge rate of the timer to protect the battery. This does present some limitations but offers a simpler design that is easy to scale; a system that does not need continuances power and is safe.

Design

Because this device will not be in a temperature controlled environment, I recommend all components have a maximum operating temperature of at least 70C and a minimum of at least -25C. Although 70C is higher than any expected air temperature, the charger will be sitting in the sun, pushing the device temperature higher and could easily reach temperatures over 50C.

First, we need to select a solar panel. I selected a 5 W panel, it has an open circuit voltage(Voc) of 22 V and a short circuit current(Isc) of 300 mA. The high voltage of this panel allows it to be used to charge 12 V car batteries, something I thought desirable. It was also pretty affordable. The 300 mA current does limit the number of batteries we can charge simultaneously to a couple small batteries or one large one.

We talked about battery chemistry earlier, but we didn't talk about capacity or form factor. You probably have a form factor(AA, AAA, etc.) in mind as you probably have a particular device that you would like to recharge batteries for. I will be designing mine for 1100 mAh AAA Ni-MH, but the chemistry and capacity really define the electric characteristics. As a general rule of thumb, the larger the battery, the greater the capacity. However, subtle differences in the packaging and technology mean that one AAA may have a different capacity than another AAA.

We have a power source, and batteries to charge, so let's start the rest of the design work. I mentioned earlier that I would be using a comparator which means we need a reference voltage. Often, this can be done with a voltage divider, but because our power supply is highly variable, I chose to use a voltage regulator. The LM317 is a common voltage regulator, easy to use, inexpensive, and has a high operating temperature. The output voltage is controlled by 2 resistors. I will use a second Second LM317 to make a 12 V line that I will use as VCC for the rest of circuit.

Lm317 configured for an output of 1.47V

Lm317 configured for 12V output

For the transistor for the LED, I used a 2N3904, the emitter was connected to a current limiting resistor and LED in series. This gives an indication of when the battery is charging and when our battery is full.

For the transistor that controls the battery current I used a IRF840 power transistor. It exceeds the specifications and is inexpensive, but could be replaced with a power transistor of your choosing. The transistor is connected in series with a current limiting resistor and the battery.

Now this will charge your battery, but I decided to go a little further, and add another system to limit the current. I added another power transistor and connected the gate to a 555 timer. The 555 timer is configured to have 80% duty cycle with a frequency of 1KHz. This limits the average current, but it also guarantees that the indicator LED will have some time with sufficient current to run bright enough to see under a bright sun.

555 timer configured for 80% duty cycle at 1KHz

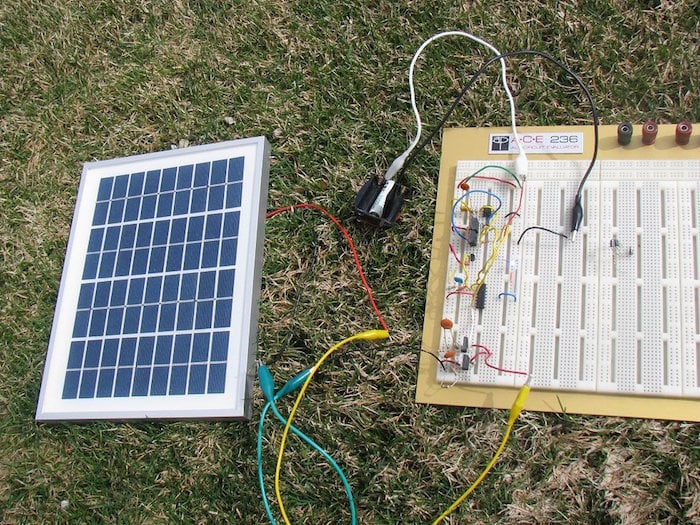

I constructed a prototype of the circuit on a breadboard with space to charge a single AAA battery. Time-averaged current flow to the battery was measured at 90 mA on a sunny winter day. I discharged and then charged four batteries with the solar charger, and then charged four with a commercial charger made by Duracell. Voltage was measured on each battery to make a limited comparison.

Battery Voltages

The Solar Charger batteries had an average voltage of 1274mV and the Duracell Charger batteries had an average Voltage of 1295mV. The slightly lower voltage is not surprising because the solar charger was designed to end the charge cycle 30mV under max voltage. You now have the complete design for your own solar charger.

Solar charger schematic for a single battery

Suggestions For Next Steps

Add more batteries

Add an indicator LED for power to the charger

Add a trickle charger after primary charge

Give this project a try for yourself! Get the BOM.

Why use another IRF840 where you have already one for the same purpose.