Industrial IoT Roundup: Magnifying the Power of Data through Communications and Analysis

The industrial IoT was the talk of Sensors Expo this year. Here's a roundup of some of the elements of the IIoT.

The industrial IoT was the talk of Sensors Expo this year. Here's a roundup of some of the elements of the IIoT.

The industrial IoT, also known as the smart factory or Industry 4.0, can be thought of as an amalgamation of three essential components used in industrial settings:

- Sensors to gather data

- A network amalgamate the date

- An analytical engine to interpret the data

Sensors have been around since forever. But in recent decades, cumbersome mechanical devices have been replaced with small, efficient, highly reliable electronic transducers. Engineers needed to find ways connect them to central hubs via wired or wireless networks. This step is already well underway and faces a tsunami of changes to be brought about by the onset of 5G.

The story of the analytical engines is just beginning, but important progress has already been made. Here's a look at the three elements of the IIoT and some contemporary examples of companies working within those spaces.

The Wide World of IIoT Sensors

If you don’t have data to work with, networks have nothing to transmit and analytical engines have nothing to analyze, so let’s first consider the most basic member of this troika, the sensors.

There are sensors on the market today that can measure any type of industrially useful parameter. These include atmospheric pressure, humidity, temperature, voltage, current, flow of fluids—the list is endless. These sensors translate physical data, such as the amount of current passing through a critical point on an instant-by-instant basis, into easily transferable blocks of digital data. The environments these sensors function in can be anything from a factory floor to a nuclear power plant or even a remote oil pipeline.

An example is the LPS22HH, a pressure sensor from STMicro. It reportedly measures pressures from 260 hPa to 1260 hPa absolute pressure range, which is about 25% to 125% of an ATM. Most importantly, it does so drawing as little as 4 μA.

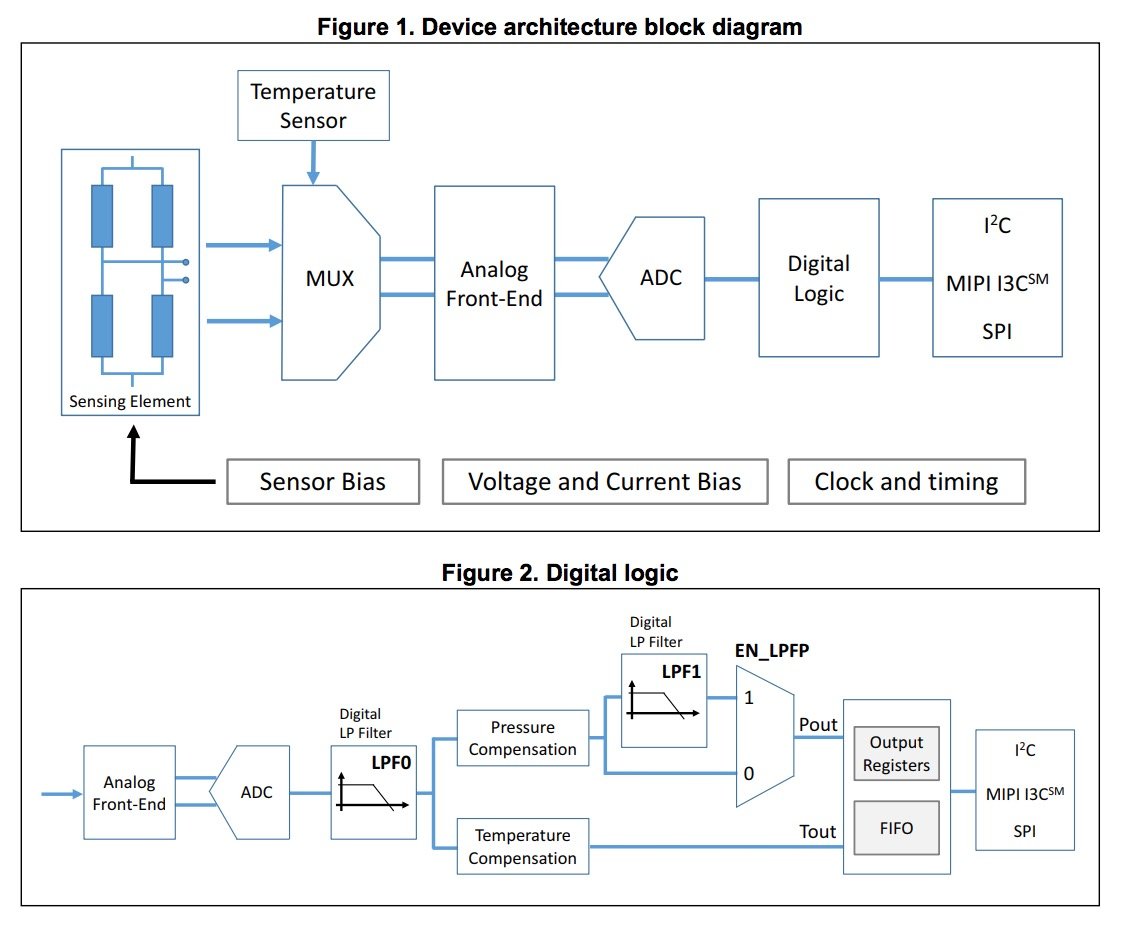

The device architecture block diagram and digital logic diagram of the LPS22HH. Image from the datasheet

The reason that the ultralow current consumption is so important harkens to one of the most important reasons for the existence of the IIoT in the first place. The IIoT can measures conditions in environments that are difficult, inconvenient, or outright dangerous for people to enter. If the sensor draws a lot of current, it will need frequent human intervention for battery replacement, destroying much of the utility of the IIoT.

These devices must therefore have connectivity baked into their basic design. Since a human won’t be directly reading the sensor, it needs to convert its electrical readings into a form readily communicable over a network. Many sensors accomplish this via formats such as the industry standard SPI and I2C data interfaces.

A real-world example is the Sure Cross U-GAGE K50U from Banner measures distances between the sensor and a target. It is typically used to measure the level of fluid in a tank. The utility here is that the tanks will very often be in remote, hostile locations, difficult to keep track of. And, a tank that unexpectedly goes dry can at least cause a line shutdown and, at worst, presage a catastrophe.

Screengrab used courtesy of Banner Engineering

The K5OU allows for fluid levels to be monitored and then the data is locally collected. From here, the data is sent to the cloud and remotely analyzed—more about that next!

The Network

Now that data is stored locally, it needs to be transported to where it can be viewed by engineering and management. That’s the job of the network. The choice of the network depends largely on two factors; how far the sensor devices are from where the data needs to be amalgamated and the necessary bandwidth.

These choices include:

- Bluetooth mesh networking (You can read more about this topic in my article on mesh networking for connected devices)

- Wi-Fi

- Li-Fi, which is similar to the more well-known WiFi, only based visible light, for very high bandwidth communications.

- Ethernet. A very well established protocol employing either copper wire or fiber optics.

- Cellular networks for remote nodes.

- VSAT (very small aperture terminal). Communications via satellite. Very useful in connecting even more remote nodes, where there is no reliable cell service.

5G – Positive Disruption Ahead!

5G is most likely to emerge as THE network choice for the IIoT. It will be an open standard available everywhere, and it will offer built-in security against hackers. It will also offer communications not only from the sensor device to hub, but also from one sensor to another, both with the lowest possible latency. This will likely mean early retirement for those sensors now on the market offering built-in communications to one of the networks described above.

According to predictions from Qualcomm, private 5G networks will be available for indoor industrial environments by the middle of 2020. A big factor that will hold back 5G for consumers is that 5G signal don’t propagate nearly as far as 4G signal do. That will translate into a need for a vast amount of 5G tower needed to service smartphone users across the length and breadth of the land. This will be no problem in controlled, indoor industrial environments.

The Analytics

Now that vast amounts of data are available throughout the organization describing the moment-by-moment condition of every monitored point throughout an industrial realm, it can now be used to great advantage. One and one will now add up to far more than two.

Honeywell Forge

Honeywell Forge is an analytical software platform targeted at the industrial sector. It amalgamates all the sensor data brought in via the networks and exploits machine learning and analytics, to enable finer control and better decisions based on the results.

The platform provides visual analytics at the enterprise level, at the plant level, and at the unit level, empowering decision makers. Information will now be simultaneously available to business, engineering, operations and maintenance teams.

Honeywell Forge Visual Analytics. Image from Honeywell

Systems like Forge will mean more than just having all the data from all the sensors available to each corporate actor simultaneously. For example, if a pipline failed in one location, the system will have all the data points recorded, not only at the moment of failure, but at all earlier times.

Was there too much pressure? Was there a seismic event? What about vandalism or sabotage?

If not something so simple, it may then use powerful analytical abilities to make comparisons to data gleaned from similar units. It will look for patterns that preceded the failure in the other units to predict and prevent similar failures before they happen.

The possibilities are, literally, endless.

IIoT Players and Standards

There are many small companies entering the IIoT fray. Many are partnering with established cloud service providers.

Interestingly, some of the cloud service providers, such as AWS, Microsoft and IBM seem interested in entering this still wide-open business more directly. This is evidenced by the fact that they are themselves actively recruiting IIoT developers to work in-house.

And, in a sign that the IIoT industry is starting to mature, the Industrial Internet Consortium (IIC), now incorporating OpenFog, and the OPC Foundation, announced they have agreed to a liaison to work together.

The IIC will supply IIoT requirements to the OPC Foundation, such as problem statements or use cases related to IoT and adjacent industry markets. The OPC Foundation will adopt these requirements in their specification development process and share use cases to IIC for consideration in IIC work.

Under “Network” - you forgot IP based Layer 4 transport networks - like (but not limited to) Public IP - the Internet !! There are also carrier based private IP transport networks that are utilized in data collection. After all - that’s the namesake of IoT and IIoT - right ??

Correction - IP Layer 3 transport networks !!