Wireless RF Energy Harvesting: RF-to-DC Conversion and a Look at Powercast Hardware

This article looks at the technology and the sample kits that Powercast provides users who want to learn more about the technology.

Energy harvesting from solar and motion are not uncommon methods for powering a system. But what about harvesting energy from RF? Here's a rundown of RF-to-DC technology and a look at a unique kit from Powercast designed specifically for this kind of power conversion.

About Wireless Energy Transfer Technology

As accelerating charges move along a conductor, they alter the electromagnetic field in the surrounding space. The changes in the electromagnetic field propagate outwards at the speed of light. To learn more, please see our articles on the introduction to antenna basics and antennna radiation patterns, permittivity, directivity, and gain.

The electromagnetic field is not constant; its intensity decreases as it spreads from the radiating element. Near an antenna, large amounts of energy can be transferred via magnetic fields. Near-field wireless transfer devices capitalize on this and can transfer watts of power over centimeter distances. Far from an antenna, a smaller amount of energy can be transferred via electric fields. Powercast uses the far field to deliver power at distances up to 25m (80ft).

In this contour-plot animation, the near field is visualized where the contours “snap” together near the antenna element

The choice of which wireless energy transfer mechanism you use depends on your application and your expected current consumption. There are several wireless charging standards competing for dominance (Qi, PMA/AirFuel Alliance, WPC, etc.), each with various charging methods and maximum charging distances. For those curious about what's inside such a device, check out our teardown of a Qi wireless charger.

Everything from our cell phones to our Wi-Fi access points to our microwave ovens creates measurable disturbances in the electromagnetic fields that surround us. Those disturbances create regions of space with potential energies that vary over time and/or distance. And wherever a potential difference exists, an enterprising engineer can always find a way to do some useful work.

One way that these electromagnetic fields can be used is energy harvesting. In particular, this can be achieved with RF-to-DC converters—harvesting energy from already present radio waves in the environment.

Harvesting Energy from RF

RF is an abundant source for energy harvesting, although it does require proximity to a transmitting antenna.

The concept of harvesting energy from RF is not new and the process is relatively simple. Radiowaves reach an antenna and cause a changing potential difference across its length. That potential difference causes charge carriers to move along the length of the antenna in an attempt to equalize the field, and the RF-to-DC integrated circuit is able to capture energy from the movement of those charge carriers. The energy is stored temporarily in a capacitor and then used to create a desired potential difference at the load.

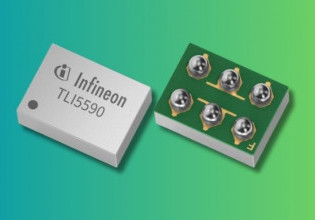

Image courtesy of Mouser

It's possible to create a circuit that performs RF-to-DC conversion for a subsystem from readily available components. Utilizing various combinations of antennas, wireless charging coils, PMICs (power management ICs), power receiver chips, exciter transmitters, etc. can yield systems capable of harvesting energy from RF. Specialized integrated circuits (ICs) designed specifically for RF-to-DC conversion are currently somewhat rare, with Powercast and E-Peas providing the only current commercial solutions.

Investigating Powercast RF Energy Harvesting Hardware

One of the only RF-to-DC converters widely available for use is from Powercast. This company has created a line of wireless RF-energy harvesting modules that operate in the far field to provide mW of continuous power to charge devices or power sensors.

According to Powercast, their RF-to-DC technology is especially appropriate for devices that can run for weeks or months off of a 3V battery (e.g., game controllers, television remotes, environmental sensors, headphones, wireless security cameras).

.jpg)

Dedicated transmitters provide the greatest amount of predictable energy in an environment. Additional sources of energy include always-on Wi-Fi and cellular antennas, and finally intermittent broadcasters. Image courtesy Powercast’s Sensor Expo Presentation.

I recently borrowed a Powercast P2110 evaluation kit, courtesy of Powercast, to explore RF-to-DC hardware in person. (Note: There was no exchange of money with Powercast involved.)

The P2110 evaluation kit contains a 900 MHz transmitter, a 2.4GHz access point, two wireless sensor modules, and two P2110 evaluation boards based on the P2110 module.

RF Harvesting Antennas

Antennas designed for the frequency of interest are connected to the RF-energy-harvesting chips, which in turn feed capacitors that store the charge.

.png)

Powercast's patch antenna (900 MHz) included in the P2110 evaluation kit. Image courtesy of Powercast

.png)

Powercast's dipole antenna (900 MHz) included in the P2110 evaluation kit. Image courtesy of Powercast

The P2110 Eval Board

The evaluation board has 12 test points to allow engineers who are evaluating the module to attach an oscilloscope probe. There is room to add additional supercapacitors (through-hole or surface mount) or attach leads for a battery. There's also a small 2.54-mm-pitch breadboard area. Evaluation boards are meant to be probed and tested so it's convenient that this board actually lets me do that.

_(Custom).png)

P2110 evaluation board. Image from Powercast

In the upper left side of the image above (near the SMA connector) is a P2110 module, shown in greater detail below.

.png)

The P2110 Powerharvester module.

The P2110 module is built around the PCC110 RF-to-DC converter and the PCC210 boost converter.

.jpg)

Block diagram of the P2110 Powerharvester module

RF energy is fed into the device where it reaches the RF-to-DC converter IC (PCC110). There, the energy can be stored in a capacitor connected to Vcap or fed to the boost converter (PCC210). The boost converter defaults to 3.3V output but can be adjusted by adding resistors to Vset. The INT pin indicates that the boost converter is operating, and a reset pin can be used to disable the converter. The DSET pin can be used to disconnect the boost converter from the RF-to-DC block for direct energy measurements from the Dout pin.

The P2110 evaluation board provides power for the WSN-EVAL-01 wireless sensor board, which has humidity, temperature, and light sensors. An additional sensor can be attached via a terminal block near the edge of the board.

The sensor board is controlled by Microchip’s PIC24F16KA102. It’s worth noting that this evaluation kit comes with a Microchip Pickit 3 in-circuit debugger and full source code for this sensor node.

.jpg)

Powercast’s WSN-EVAL-01

The PIC24F16KA102 spends most of its time in sleep mode, where it consumes several dozen nanoamperes of current. When the INT pin notifies the microcontroller that 3.3 V is available, the microcontroller wakes up, reads the sensor values, and transmits the data via the onboard wireless module to a distant access point. It then goes to sleep until the next transmission. Transmission intervals are governed by the amount of energy stored in onboard capacitors or by statements in the source code.

Why is so much board space dedicated to capacitors?

These energy-harvesting modules are designed to function as battery-replacement devices. It’s up to each engineer to calculate the power budget and decide how much storage capacity to build into the circuit. Too much capacitance results in excessive circuit size, excessive expense, and long turn-on times. Too little capacitance and the supply voltage might drop below necessary operating levels before the circuit has completed its designed task. I’ll walk you through what that looks like in the experiments that follow.

The evaluation board contains a 1 mF (C3) and a 50 mF (C5) capacitor on board as well as ample room to add additional capacitors for testing. Let’s take a look at the voltage over time using two different capacitors. The first experiment is with the 50 mF capacitor connected on the board. This is accomplished by setting JP1 to position C5. You’ll note that the traces are quite “fuzzy”, which I’ll explain in a moment.

.png)

Vout measured while using 50 mF capacitor. Images captured with Tektronix MDO3104 mixed domain oscilloscope.

Next, I disconnected the 50 mF capacitor and connected the 1 mF capacitor by moving the jumper to C3. You’ll see that the voltage only gets up to around 2.5 V and immediately begins to fall back to the original level. The voltage isn’t high enough, long enough, to allow the microcontroller to read the sensor values and transmit them.

.png)

Vout measured while 1 mF capacitor was connected.

So what is happening in the circuit? We can learn more by monitoring the capacitor voltage while looking at the output voltage. First, though, let’s talk about the fuzziness of the traces.

If we zoom in, we see a well-formed sine-wave. And it just happens to be at the transmission frequency of the Powercast transmitter. Either something in the circuit or the oscilloscope probe is acting like an antenna and picking up that radio energy, superimposing the 915 MHz carrier on everything I’m measuring.

.png)

The 915 MHz transmission shows up as an artifact on all measured signals.

Next, let’s look at what the capacitor voltage is doing in the period corresponding to the output-voltage waveform shown above. We’ll first look at the case with the 50 mF capacitor.

.png)

Vout is measured on channel 1 (yellow) and Vcap is measured on channel 2 (cyan)

You’ll notice that while Vout is at 3.3V, the capacitor voltage drops steadily, but the overall decrease is not more than 0.2 V. That’s to be expected and it's not a problem, as long as the capacitor voltage stays above the shutdown voltage of the boost converter.

Next, let’s consider the case with the 1 mF capacitor.

.png)

Vout is measured on channel 1 (yellow) and Vcap is measured on channel 2 (cyan)

You’ll note that as Vout rises suddenly, Vcap decreases significantly, followed immediately by Vout decaying. That sudden drop of approximately 0.5 V across the capacitor is just too great, and the boost converter shuts down. Slowly, the capacitor voltage will rise, the boost converter will turn on, and it will all happen again in an endless cycle of failure. Sudden drops like that are never good, and that the voltage increased immediately after leads me to believe that the 1 mF capacitor that I’m using has an ESR (Equivalent Series Resistance) that is too high.

It should be possible to augment the 1 mF capacitor with one or more decoupling capacitors with low ESR to smooth out that drop. The dropout voltage for the boost regulator would dictate whether a significant increase in capacitance is required.

I imagine that situations like these are why Powercast included so many capacitor mounting options and test points on the evaluation board—they want designers to be able to quickly and easily determine if a capacitor they’ve chosen for their application will meet the demands of their design.

Broadcast Spectrum of the Transmitter

The Powercast transmitter operates in the 902-928 MHz ISM (Industrial, Scientific, and Medical) band along with some radiolocation and amateur radio services.

In the United States, the FCC (Federal Communications Commission) is responsible for determining what frequencies are used for what purpose. Click to enlarge

The Powercast transmitter is centered at the middle of this band. The image below shows the frequency spectrum of the test environment from 0 MHz to 3 GHz. A clear peak is shown at 916 MHz, as well as two lesser peaks that correspond to broadcast channels and the 2.4 GHz ISM band (Wi-Fi, Bluetooth, microwave ovens, etc.).

3 GHz spectrum and waterfall plot centered at 1.5 GHz while the Powercast transmitter is running. Data recorded with the Tektronix MDO3104 Mixed Domain Oscilloscope

Narrowing the span shows the transmission in greater detail. Remember that the ISM band in question spans 916 MHz ±15 MHz. The image below shows the entire range of the ISM band.

.png)

30 MHz spectrum and waterfall plot centered at 915 MHz while the Powercast transmitter is running. Data recorded with the Tektronix MDO3104 mixed domain oscilloscope

You can likely tell from the image above that the Powercast transmitter is able to keep its transmission within a small enough portion of the band that there is still plenty of room for data transmission on other frequencies. The transmission is centered at 915 MHz and falls off ~50 dB within 3 MHz of the center frequency.

Conclusion

RF energy-harvesting ICs have been around for quite some time. As future ICs continue to have lower and lower power requirements, otherwise wasted energy in the environment might be harnessed to provide a batteryless application for your next design. You probably know how to harvest energy from light and perhaps even movement—why not add RF energy to your bag of tricks?

.jpg)

.png)

Hi Mark,

Thanks for the thorough analysis on the capacitor options/preferences. I have another question though, in the article you wrote:

“The PIC24F16KA102 spends most of its time in sleep mode, where it consumes several dozen nanoamperes of current. When the INT pin notifies the microcontroller that 3.3 V is available, the microcontroller wakes up, reads the sensor values, and transmits the data via the onboard wireless module to a distant access point. It then goes to sleep until the next transmission. Transmission intervals are governed by the amount of energy stored in onboard capacitors or by statements in the source code.”

My question is, is this thing able to supply that “dozen nanoamperes of current” when the regulator is OFF (i.e. when Vcap < Vmin)? Isn’t the output (Vout) turned off when the capacitor is charging up?