Georgia Tech Research Aims to Solve Organic Thin-Film Transistors’ Stability Problem

Georgia Tech's Center for Organic Photonics and Electronics (COPE) has made a large improvement of the operation and stability of organic thin-film transistors (OTFTs).

Georgia Tech's Center for Organic Photonics and Electronics (COPE) has made a large improvement of the operation and stability of organic thin-film transistors (OTFTs).

TFTs (thin-film transistors), as their name suggests, are Field-Effect Transistors (FETs) with an active layer constructed from a thin film, usually comprised of a silicon semiconductor. TFTs are best-known for their use in many modern LCDs, allowing active-matrix LCD functionality wherein each pixel is actively maintained, improving image stability.

In recent years, researchers have been investigating OTFTs—organic TFTs—that could be more flexible than their non-organic counterparts. Georgia Tech has publicized some improvements to the technology that could make them viable for widespread use.

OTFT vs TFT

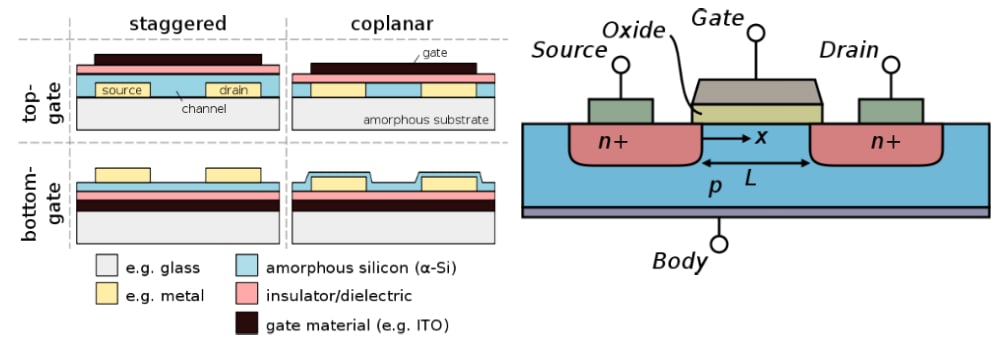

An OTFT is essentially the same component in terms of design and function as a typical TFT, but uses an organic film. This organic film gives the TFT the advantage of using a much wider range of substrates compared to the restricted FET structure illustrated below.

An OTFT is a three-terminal device where an applied voltage is transmitted through the gate electrode and allows current to flow between a source and drain electrode under an imposed bias.

TFT structure (left) vs FET structure (right). Image courtesy of Cepheiden [CC BY-SA 3.0]

Over the last decade or so, the development of organic thin-film transistors has significantly increased. This is not to say that OTFTs will replace TFTs—while the OTFTs have much greater mechanical flexibility due to their organic structure, inorganic TFTs have much greater switching speeds that have not been achieved in OTFTs, yet.

Another benefit of OTFTs is that their carrier mobility is reaching the speeds of TFTs. According to Zhenan Bao, a chemical engineering and materials science professor at Stanford University, new techniques have allowed OTFTs to reach carrier mobility speeds of 5 to 15 cm2/Vs with a few outliers at 108 cm2/Vs. Standard poly-silicon TFTs typically have speeds around 100 cm2/Vs. If Bao and his colleagues can refine his technique and make that outlier the norm, we might have a breakthrough for OTFT technology.

You can read about the research on OTFTs Bao and others have done here for more details.

Recent Accomplishments by Georgia Tech's COPE

One of the most significant obstacles facing OTFTs' versatility is their stability. However, Bernard Kippelen, holder of the Joseph M. Pettit professorship from Georgia Tech, has discovered that a nanostructured gate dielectric might be the solution to this issue.

They believe that this structure, which is composed of a fluoropolymer layer followed by a nanolaminate is the right combination. The nanolaminate is comprised of two metal oxide materials that serve the gate dielectric while helping protect the organic material.

Their first iteration used aluminum oxide but that proved to be prone to damage from exposure to humidity. Canek Fuentes-Hernandez, senior research scientist and co-author of the paper stated that "Working in collaboration with Georgia Tech Professor Samuel Graham, we developed complex nanolaminate barriers which could be produced at temperatures below 110 degrees Celsius and that when used as gate dielectric, enabled transistors to sustain being immersed in water near its boiling point." For their experiment, they used a glass substrate but claim that many other flexible materials such as paper could be used.

Georgia Tech's OTFT concept being tested by probes. Image courtesy of Rob Felt, Georgia Tech

Prior to using this dielectric material, the OTFT was left vulnerable even in an ambient environment. This is a huge accomplishment for OTFT technology because not only can the transistor be flexible but it is very inexpensive to create. OTFT can be manufactured on various substrates by inkjet printing (yes, inkjet printing).

Kippelen believes that this is just the tip of the iceberg for OTFT technology. It's been a long time coming; COPE has been researching and developing their progress on OTFTs for over 15 years with various funding from sponsors such as the Office of Naval Research.

While the researchers at COPE have made huge improvements to the stability and operation of OTFTs, they still have a long way to go says Kippelen says.

Their next steps? "We will get better image quality, larger size, and better resolution."