Three-Phase BLDC Motors Save Energy in Appliance Systems

This article looks at how appliance design is utilizing three-phase brushless DC motors to reduce system power consumption to meet Energy Star's requirements.

Home appliances have traditionally used AC induction motors, but as energy efficiency gains popularity a new challenge emerges: to find solutions that won't interfere with performance. This article explores the utilization of three-phase brushless DC motors as a design solution.

The growth and expanded innovation of home appliances goes hand in hand with energy-efficiency and energy-saving regulations and certifications with which appliance makers must comply. For example, one of Energy Star’s requirements is power reduction while maintaining robustness and high performance. Therefore, reducing overall system power consumption helps appliance makers comply and achieve certification.

In order to save power, many applications are transitioning to three-phase brushless DC (BLDC) motors for operation, including refrigerator circulation and compressor fans, washing machine drain and water pumps, air purifiers, air exchangers and ceiling, exhaust and pedestal fans (see Figure 1). The power required for home appliances can be as high as 80W, whereas for industrial applications the power can be as low as 5W to kilowatts.

Figure 1. Typical home appliances.

Historically, home appliances used single-phase AC induction motors. With the development of motors with permanent magnets, many companies can now develop and produce low-cost three-phase BLDC motors with small sizes that support the same torque levels as single-induction motors. Although BLDC motors are physically and mechanically complex, they are more efficient, quiet and flexible for system designs compared to single-phase AC induction motors. In this article, I’ll provide some insight into how TI’s BLDC motor-drive technology is simplifying and helping appliance manufacturers design and achieve high-efficiency, ultra-quiet operation and reliable motor systems.

Difference Between Single-Phase AC Induction and Three-Phase BLDC Motors

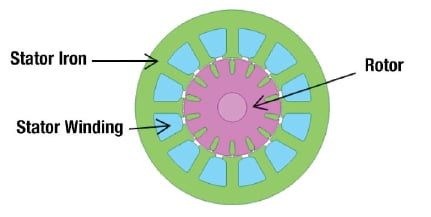

As shown in Figure 2, the single-phase induction motor consists of a rotor and a stator. The stator is stationary, whereas the rotor rotates to generate magnetic fields that are used to generate torque. In addition, single-phase AC induction motors have stator and rotor windings and slippage frequency.

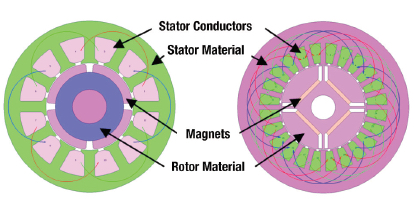

BLDC motors (see Figure 3) have a stator and rotor as well; however, the rotor is a permanent magnet. Because the windings are mounted on the stator, there are no rotor winding losses.

The slippage frequency, which is the difference between the magnetic field and the motor rotating speed, causes problems with motor speed control for single-phase AC induction motors. BLDC motors synchronize the speed between the stator and rotor, making them easy to control.

Figure 2. Example of a single-phase AC induction motor

Figure 3. Example of a three-phase BLDC motor

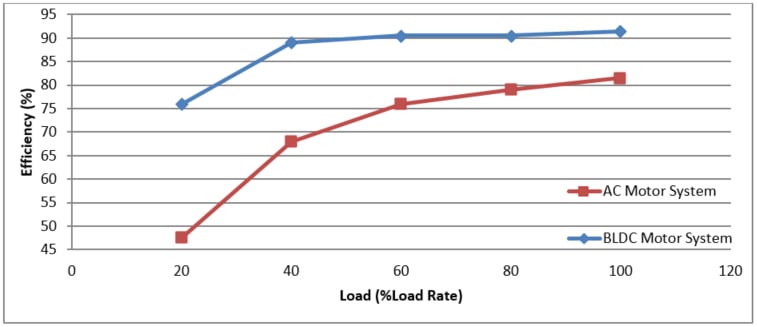

Figure 4 illustrates the power efficiency for each motor type under the same load conditions, collecting data using motors with less than 100W. You can clearly see that for low-power (less than 100W) applications, three-phase BLDC motors provide high efficiency. In addition, BLDC motors have long life and very low electric noise due to the lack of brushes, making them reliable for various applications, including appliances.

Figure 4. Efficiency comparison

Geographic regions have different power-outlet ratings for different applications, which stipulate the power and frequency for single-phase AC induction motors. For example, the U.S. requires AC lines that are 120VAC with 60Hz; Europe requires a 230VAC line with 50Hz. This is important, as designers must use different single-phase AC motors to adapt to regional power requirements, which can complicate circuit designs. In addition, single-phase AC induction motors that directly connect to the AC line do not give users the flexibility to control the motor speed.

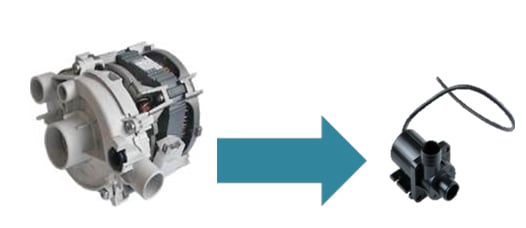

Another advantage to using BLDC motors for low-power applications is that their size is up to five times smaller compared to single-phase AC induction motors (see Figure 5). Furthermore, single-phase AC induction motors generate intensive electrical and mechanical noise during operation which can be uncomfortable depending on the application.

Figure 5. Single-phase AC induction vs. three-phase BLDC motors

Three-phase BLDC motors require additional circuitry to drive and control the motor, and it can be difficult and overwhelming for less-experienced designers to move from single-phase AC induction motors to three-phase BLDC motor systems due to design complexity. However, TI motor drivers make the transition of moving from single-phase AC induction motors to three-phase BLDCs easier. For an in-depth tutorial on moving from single-phase to three-phase BLDC motors, this white paper (PDF) explains more about energy reduction.

TI’s integrated motor-driver portfolio integrates control logic, gate drivers and field-effect transistors (FETs) in a single package, enabling you to design simple and cost-effective motor control. The DRV10987 achieves high efficiency and ultra-quiet performance with TI’s proprietary 180-degree sensorless sinusoidal algorithm. This integrated solution has products to support both 12V and 24V bus voltages. These are common voltages for appliance applications.

For example, the DRV10987 is a good fit for 24V systems and has adjustable slew rate and output pulse-width modulation (PWM) frequency for electromagnetic interference (EMI) management. These features help eliminate the external circuitry required for filtering EMI and thus reduce overall bill-of-materials (BOM) cost and conserve printed circuit board (PCB) board space.

In addition to the complete portfolio of intelligent motor drivers, TI also has fully tested reference designs for washers/dryers, refrigerators, air purifiers, humidifiers and residential fans. These reference designs have test data, source files and design guides to help you develop and simplify the design for your products, enabling quick time to market. For example, the 24V, 50W BLDC Motor Sinusoidal Drive Reference Design for Air Purifier Fans is based on the DRV10983 three-phase sinusoidal motor driver.

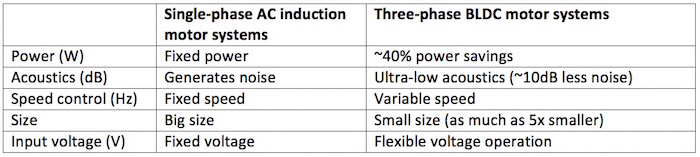

Table 1 summarizes the advantages of using three-phase BLDC motors vs. single-phase AC induction motors.

Table 1. Comparison Between BLDC and AC Motor Systems for Appliances

TI’s integrated motor-drive products are helping to facilitate the transition to much simpler, robust, and smaller three-phase BLDC systems for low-power appliance applications with products that help reduce power consumption and other design complexities while maintaining high efficiency and quiet operation.

Industry Articles are a form of content that allows industry partners to share useful news, messages, and technology with All About Circuits readers in a way editorial content is not well suited to. All Industry Articles are subject to strict editorial guidelines with the intention of offering readers useful news, technical expertise, or stories. The viewpoints and opinions expressed in Industry Articles are those of the partner and not necessarily those of All About Circuits or its writers.